Production is a part of the Advanced inventory management and is available only to those users who have subscribed to this functionality.

The production functionality allows you to keep a record of the inventory of produced items, not just their components. It can be useful for items that are made in advance, not during ordering. For example, in a bakery. Produced items can be moved between stores, its inventory could be adjusted and counted.

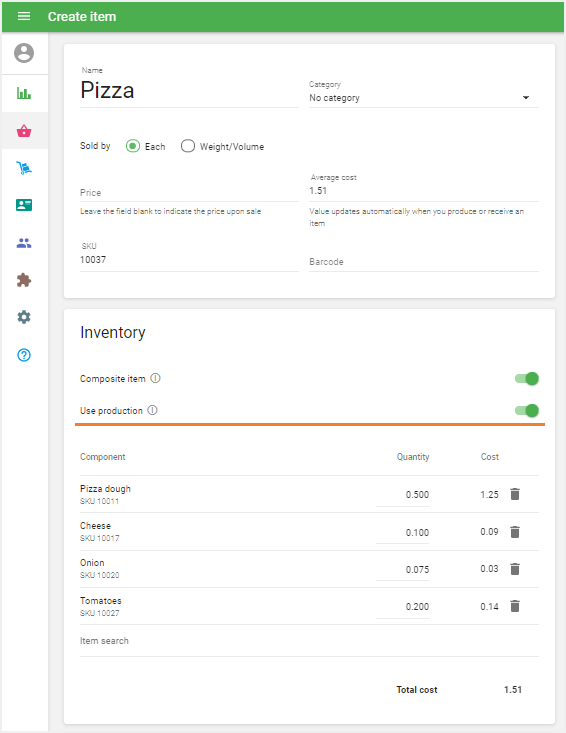

The production option is only available for composite items.

Open the composite item to edit or create a new one. Switch on the ‘Use production’ option in the Inventory section.

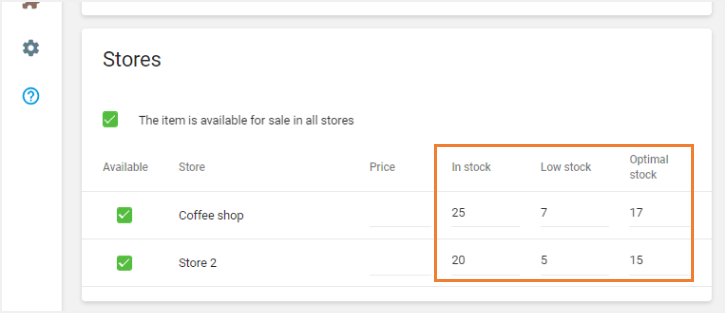

When the option is enabled, the fields ‘In stock’ and ‘Low stock’ will appear in the item form. You can set these values for the composite item manually, and this will not influence the stock of the ingredients.

From now on, the stock of the ingredients will be changed by creating Production or Disassembling (explained later).

When selling an item with the "Production" option on, the stock of the composite item will be reduced, but not its ingredients.

Don’t forget to save the changes.

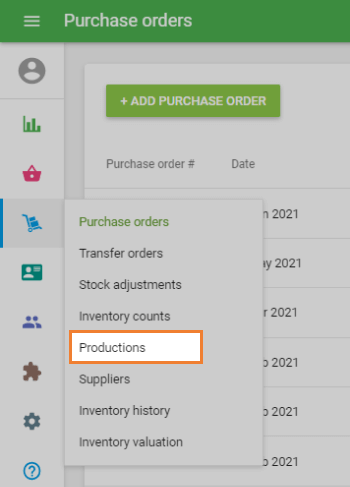

Go to the ‘Production’ section in the ‘Inventory management’ menu.

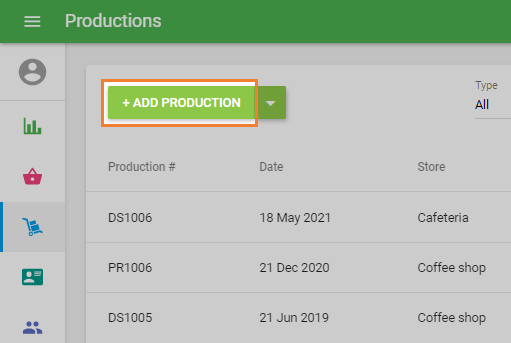

To create a production, click on the ‘+ Add production’ button.

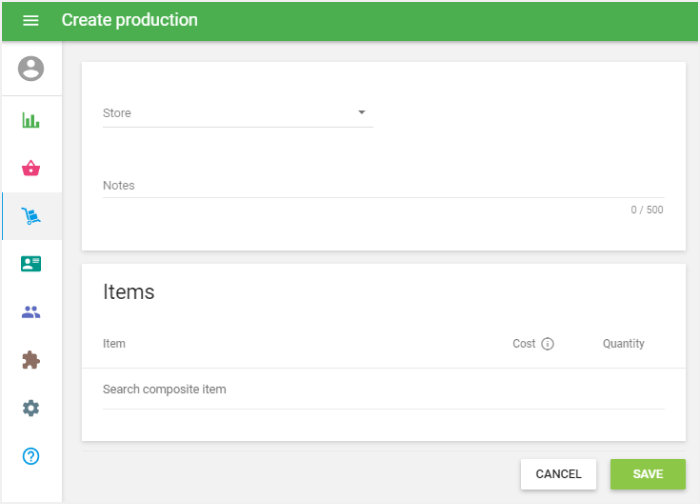

The form ‘Create production’ will open for editing.

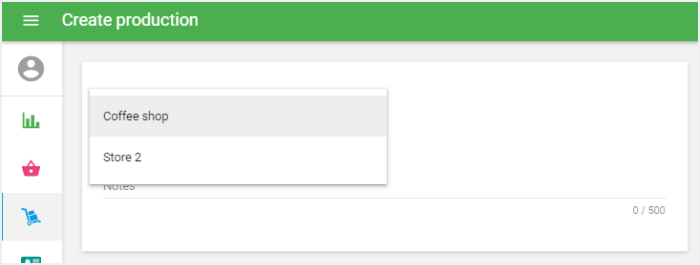

Select the store from the drop-down list where you would like to perform the production. You can also make notes in the ‘Notes’ field.

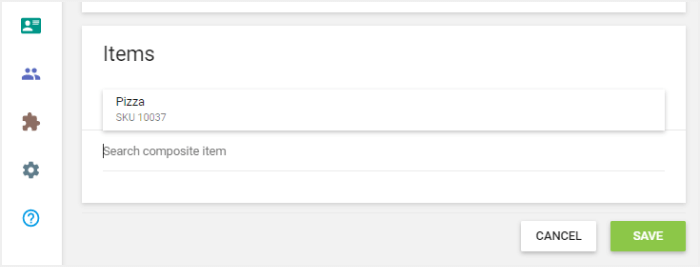

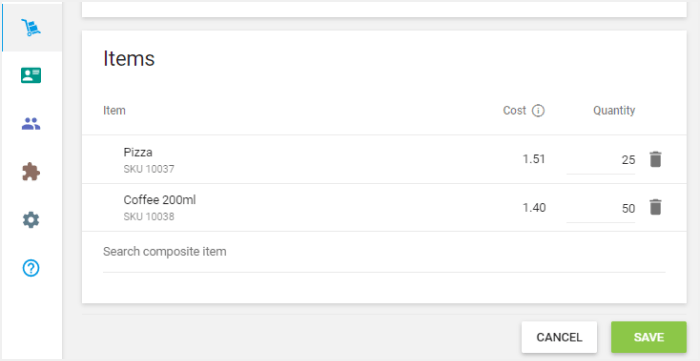

In the ‘Items’ section, you can find and add items from the list of your composite items in which the production option has been switched on. If you click on the field, a drop-down list of your items will appear, and you can type in the item’s name, SKU, or barcode to find the desired item.

The ‘Cost’ field reflects the value that is calculated based on the cost of the components of the item.

Fill in the ‘Quantity’ field with the quantity of each product that you want to produce.

You can add more items to the order in the same way as above.

Click on the ‘Save’ button to create a production.

Afterward, the stock of the produced composite items will be increased according to their quantity; the stock of the components of the produced items will be decreased based on their use in the produced composite items.

Also, the value of the average cost for each produced composite item will be updated.

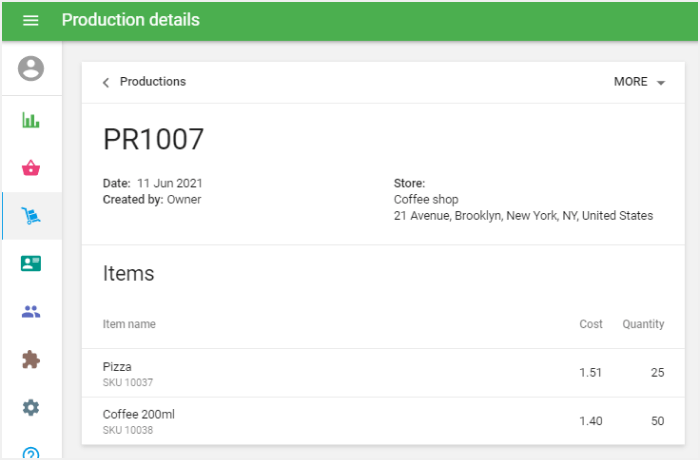

Now you will see the created production document.

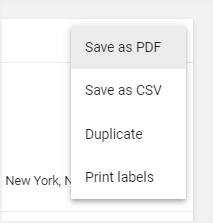

There are operations available with the production document in the ‘More’ menu: Save as PDF, Save as CSV and Duplicate.

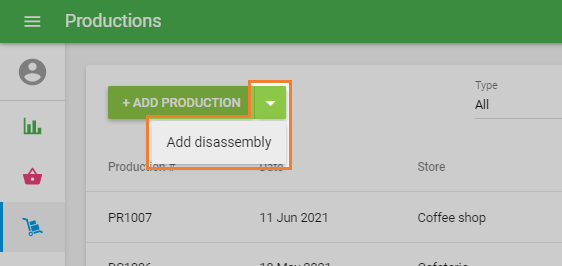

If you want to disassemble the produced composite item, click on the down arrow and select ‘Add disassembly’.

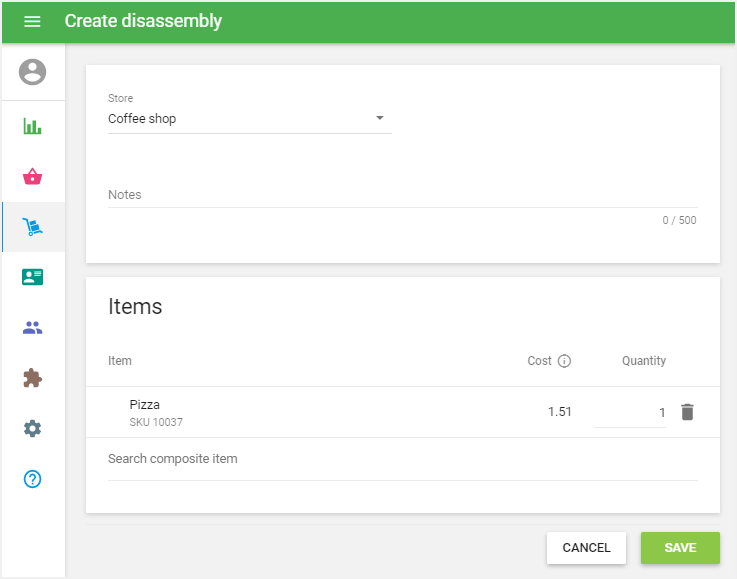

Fill in the ‘Create disassembly’ form in a similar way as ‘Create production’.

After clicking on the ‘Save’ button, the stock of the disassembled composite items will be decreased by the mentioned quantity and the stock of their components will be increased based on their use in the produced composite items. The cost of the components is also renewed.

See also:

Advanced Inventory Management Overview

How to Work with Purchase Orders and Suppliers

How to Work with Transfer Orders

How to Work with Stock Adjustments

Inventory History and Valuation Report