The ‘Advanced inventory management’ includes a set of additional functions in the Back Office that allows users to more efficiently keep track of items in stock, monitor any changes in the inventory, and also launch a mechanism for more accurate calculation of business profitability indicators.

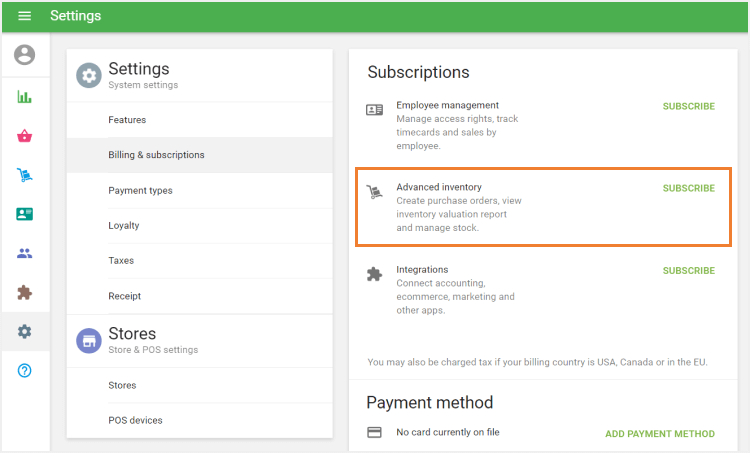

The ‘Advanced inventory management’ is only available in the paid subscription.

To activate a subscription or a trial period, go to the ‘Billing & subscriptions’ section in the Settings menu of the Back office.

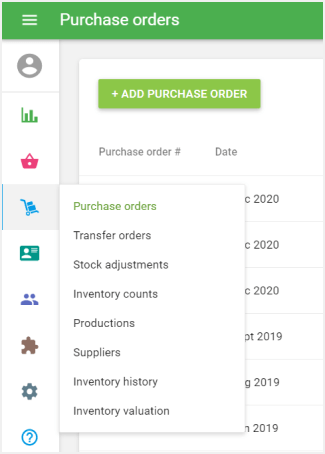

After activation, the ‘Inventory management’ menu will appear in the Back Office.

The ‘Inventory management’ menu includes:

Purchase orders - allows you to create and save orders for the supply of products, send orders to suppliers, receive products, and save information of suppliers in the system.

Transfer Orders - allows a multiple store owner to distribute items correctly between his/her stores.

Stock Adjustments - allows you to modify the stock of items and indicate the reason for that adjustment.

Inventory history - allows the user to view records of all the changes made in the inventory, including transfers, purchase orders, and adjustments.

Inventory Valuation Report - gives an understanding of the total cost of the inventory and potential profits from their sale.

Inventory Counts - allows you to reconcile the expected and actual inventory for all or selected items, see the amount of inventory loss or surplus inventory, and keep documents for each inventory.

Print Labels - this button will appear in the Items list as a part of the Advanced inventory management. The label can contain the item’s name, SKU, price, and barcode. Labels with a barcode allow you to use the scanner to add items to the ticket.

Productions - allows you to keep a record of the inventory of produced items, not just their components. It can be useful for items that are made in advance, not during ordering. For example, in a bakery. Produced items can be moved between stores by using inventory adjustments and inventory counts.

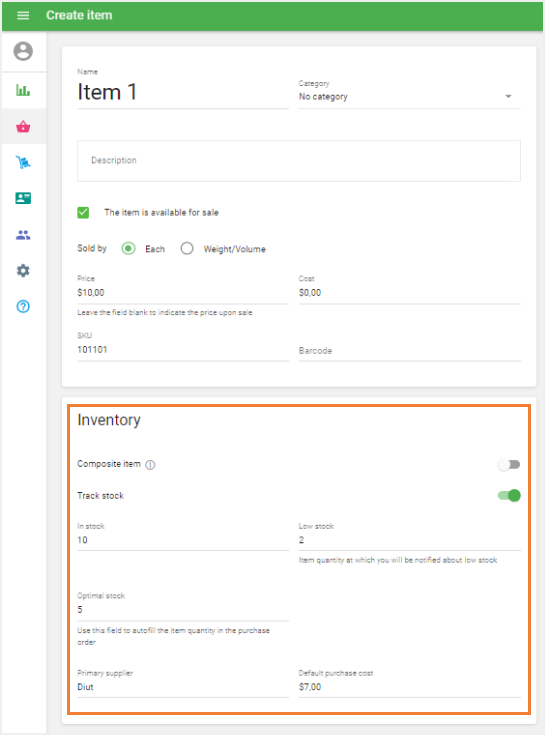

The Advanced inventory option alters the appearance of the Items form and the way items’ cost is calculated.

When you create a new item, you can fill in the Price and Cost as usual. However, when you switch on the ‘Track stock’ feature in the Inventory section, you will see additional fields that are only available with an advanced inventory. For ‘Primary supplier’, you can assign a certain supplier for the product from the list and set the ‘Default purchase cost’.

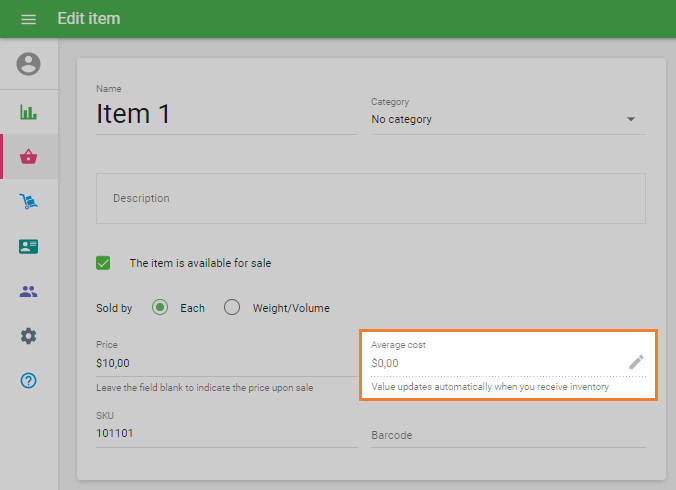

After you save the changes and open the item for editing again, the ‘Cost’ field will be changed to the ‘Average cost’ field. It will be calculated automatically when you receive items using the advanced inventory functionality.

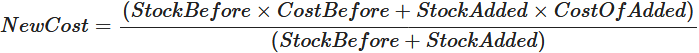

The value of the item's average cost after receiving new items (NewCost) is calculated as:

StockBefore - stock before receiving new items

StockAdded - quantity of received new items

CostBefore - cost before receiving new items

CostOfAdded - cost of received new items

This value of the cost will be used in all the reports and calculations of all other values.

See also:

How to Work with Purchase Orders and Suppliers

How to Work with Transfer Orders

How to Work with Stock Adjustments

Inventory History and Valuation Report

How to Work with Inventory Count